题目:Laser polishing of powder bed additive manufactured Ti6Al4V components and its influences on subsurface materials

时间:2018年5月24日 10:00-11:00

地点:80足球直播吧 F301会议室

邀请人:张超群博士(汽车工程研究院)

Biography

Dr Yingtao Tian received BEng & MEng in Welding Science and Technology from Harbin Institute of Technology, and PhD in Mechanical Engineering from Loughborough University in 2010. He then worked as a knowledge transfer researcher at Rutherford Appleton Laboratory in 2011 developing a novel process of producing high density interconnections. In 2012, he started working at University of Birmingham on developing high precision manufacturing process for terahertz microwave components. He successfully assembled the first 700GHz waveguide based on 3D stereolithographic processing of SU8. In 2013, he moved to The University of Manchester working on laser processing of aerospace materials, laser-materials interaction, post-processing of additive manufactured components, laser welding of dissimilar materials and advanced materials characterisation techniques etc. Since 2018, he joined the Department of Engineering at Lancaster University as a Lecturer and his research interests focus on advanced laser processing, additive manufacturing & 3D printing, micro-fabrication etc.

Abstract

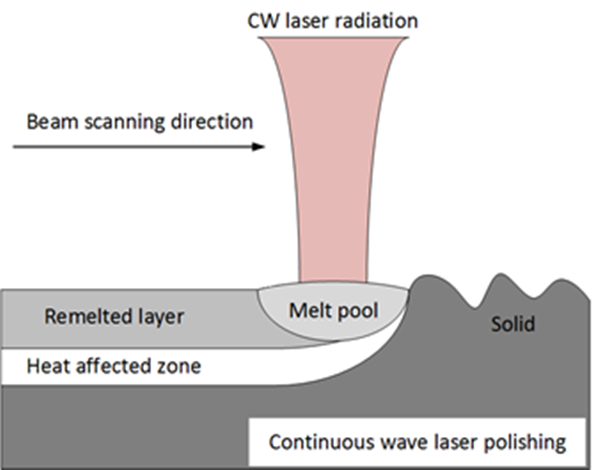

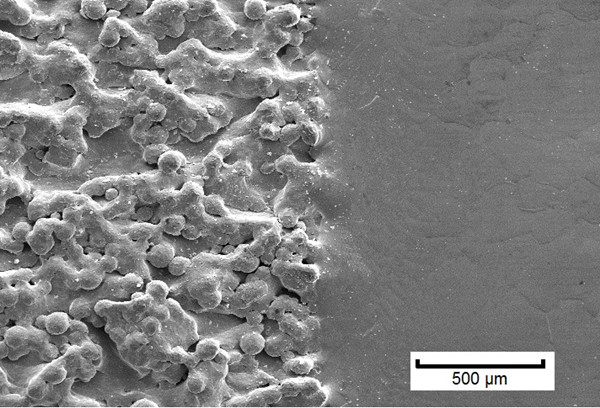

Additive manufacturing (AM) is a key enabler for high value manufacturing because it can offer several benefits such as design freedom, digital manufacturing flexibility and flat cost to volume ratio. It has been highlighted as a revolutionary technique that can dramatically change the way components are designed, developed, manufactured and supplied. During powder bed AM process, one of the most matured AM processes, the poor surface finish, due to the partially melted metal powders on the outer surface, needs to be smoothed for both tribological and aesthetical purposes. This study is to investigate the capability of using laser polishing to reduce the surface roughness of the AM component and, more importantly, the influences on the subsurface materials.